In the field of control room equipment, Chinese manufacturing is undergoing a magnificent transformation from “low-cost OEM” to “high-end intelligent manufacturing.” As a participant and witness to this process, WuBang has consistently adhered to a global perspective in product R&D since its founding in 2013. Today, WuBang consoles are widely used in public security, aviation, and energy centers across more than 30 countries and regions.

The primary passport to international markets is “Standards.” WuBang is fully aware that high-end control room projects have nearly strict requirements for safety and environmental protection.

Quality & Environmental Management: WuBang has successively passed ISO 9001 (Quality), ISO 14001 (Environment), and ISO 45001 (Occupational Health and Safety) certifications. This means every step from raw material entry to finished product delivery is documented, ensuring consistent quality.

Safety Access: Our products have obtained CE Certification and SGS Test Reports. Especially for European and American markets, the electrical components and structural safety of WuBang consoles fully comply with international access standards, eliminating worries for system integrators during project acceptance.

In an enclosed monitoring center environment, air quality directly impacts operator health. WuBang insists on using materials and powder coating processes that meet E1 environmental standards certification.

Zero Formaldehyde Risk: The Phenolic Compact Laminate (HPL) used by WuBang is not only wear-resistant and fireproof but also ensures no harmful substances are released during high temperatures or long-term use.

Sustainable Development: Our manufacturing processes focus on resource recycling and low energy consumption, aligning with the global procurement trend for “Green Supply Chains.”

For international trade, shipping costs and on-site installation difficulty for bulky furniture are core pain points. WuBang introduced Full Modular Design early in the R&D stage.

Flat Packing: Modular components can be compactly flat-packed, significantly improving container loading rates and saving overseas customers over 30% in logistics costs.

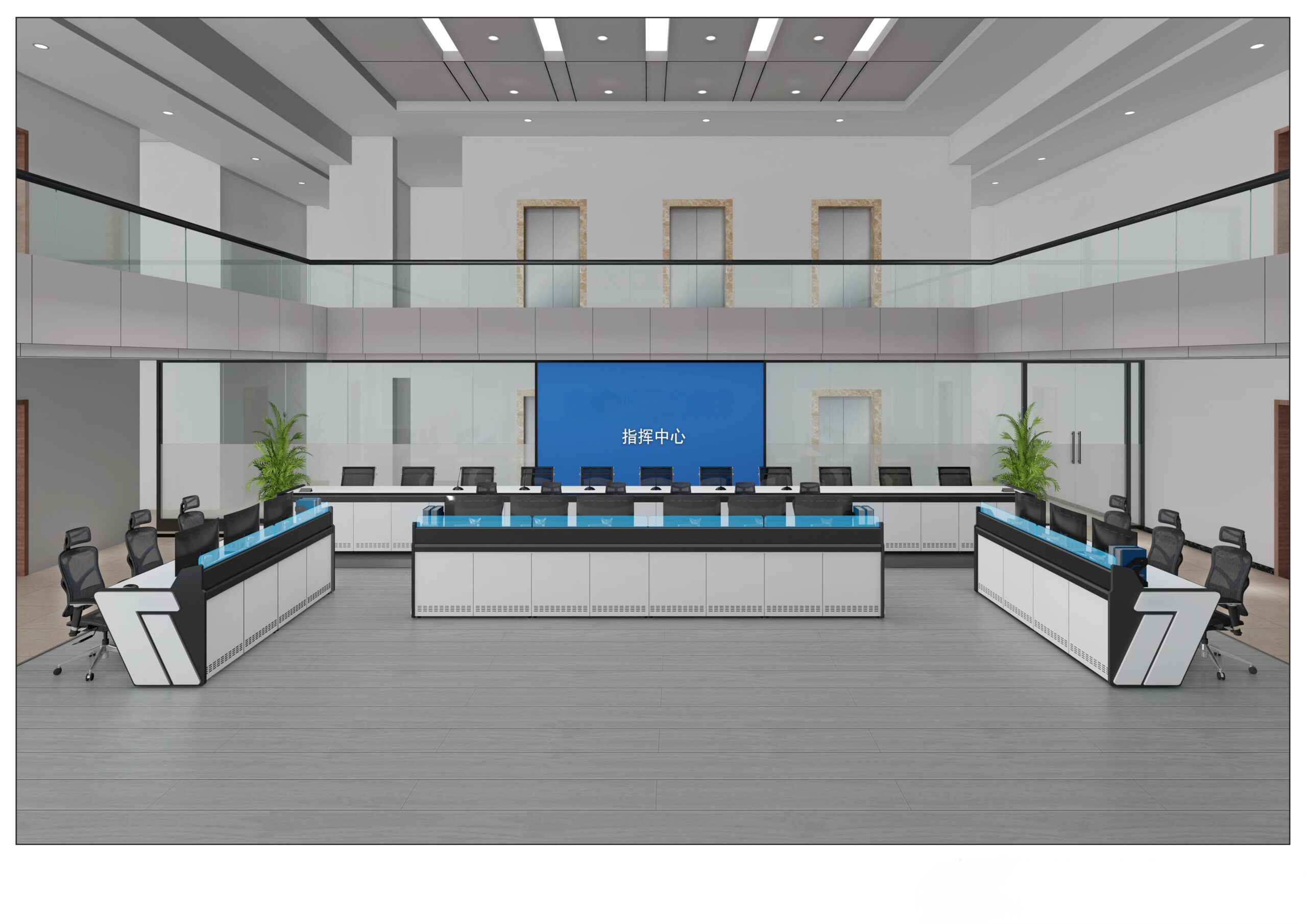

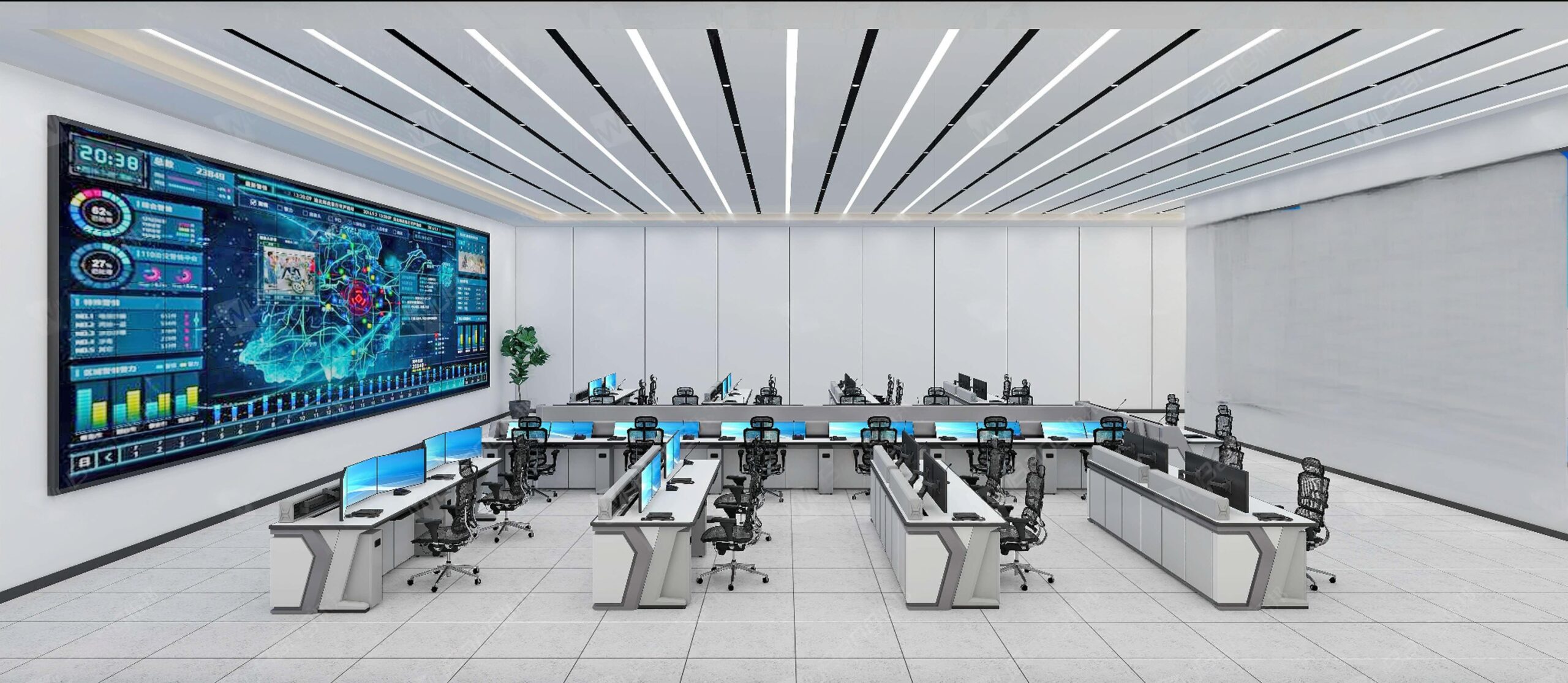

“Zero Welding” Assembly: On-site, workers only need to follow WuBang’s detailed drawings for bolt connection, without the need for hot work or professional welding. This standardized process ensures that whether in a Southeast Asian traffic center or a Middle Eastern energy station, WuBang consoles present a consistent industrial aesthetic.

WuBang (Guangdong) Intelligent Control does more than sell products; we are deeply rooted in industry collaboration. We know that the console is the “last mile” of system integration.

3D Rendering & Support: For export inquiries, WuBang’s technical team can provide preliminary 3D layout designs within 24 hours, assisting system integrators in completing bid proposals.

Global Case Endorsements: From the Wuhan City Brain to overseas transportation projects, WuBang has accumulated extensive turnkey project experience. These successful endorsements are the strongest driver of our global expansion.

“WuBang” is more than just a brand name; it represents the fusion of Chinese craftsmanship and modern industrial design. By continuously participating in international competition, we tell the Chinese story through the “international language” of ergonomics. In the future, WuBang will continue to strive to provide a more scientific, comfortable, and secure control environment for every operator worldwide.